As the winter season has passed and contractors are getting to repairs on public use land, one of the barriers that holds back safe public use is damaged retaining walls. They are built for a reason, and maintaining their structural integrity to literally, retain what’s behind them, is best done with solutions that make permanent repairs. For solid block retaining walls, that product is Torque Lock.

Australian contractor Steve Pisceteck explains, “We are lucky in the sense we have relatively benign soils in most cases. Different soils behave very differently, and along the coast the dune sands are very benign. But then as we move towards the hills, we start getting into clays. Clays tend to swell and shrink much more rapidly when the moisture content changes. And that’s generally where we see more of the structural problems.”

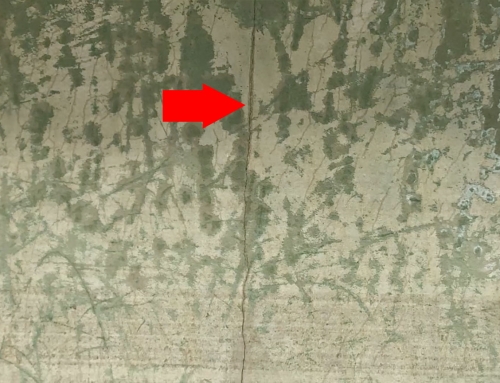

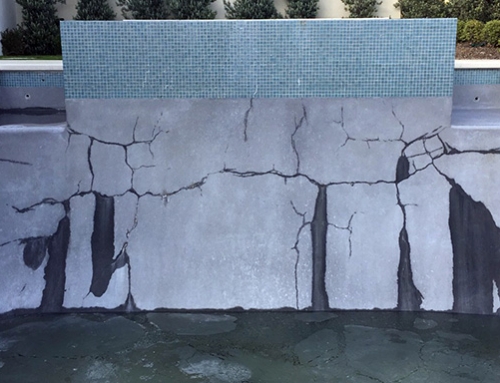

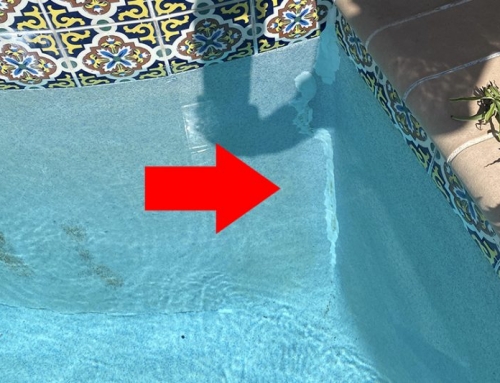

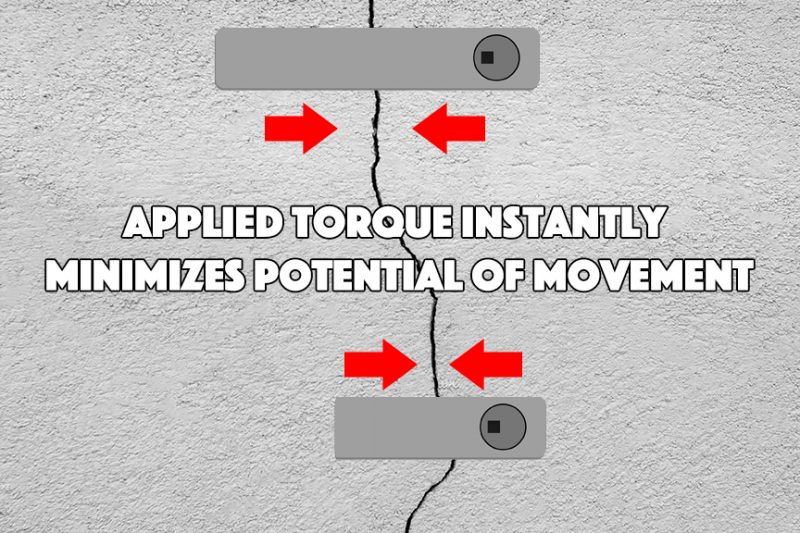

As structural cracking begins to show in weakened areas, getting the crack stabilized immediately keeps the integrity of the wall intact so cracks don’t widen or lengthen when soil movement takes place. By stitching the crack with Torque Lock Structural Staples, the strength of the wall stays in place.

Installing a Torque Lock Staple every 12 inches along the linear footage of the crack applies a controlled compression that doesn’t allow the concrete to spread. Where the applied pressure of shifting soil behind the wall presses against its back side, the compression made by the staples holds the wall in place. Repaired concrete stays in the crack and repaired walls retain the weight of what they are holding back.

“We have walls that contour the cart path along parts of the golf course,” maintenance Superintendent Charles Swain of Chatham Hills Golf Course shares. “It’s an integral part of the landscape and can easily become a safety hazard if dirt spills onto the path. Even a small separation is enough to disperse soil when the landscape sprinklers run. With Torque Lock, we can repair those cracks in a day.”

Small cracks will ultimately lead to bigger problems and considerable construction efforts if they aren’t handled immediately. When a solid concrete wall begins to crack, Torque Lock’s stitching method will secure the crack before it becomes an issue. By applying the controlled compression of the staples, bridging the crack with up to 5000 lbs. of resistance, the crack is secured and can be finished over to match the surface of the wall.

Scottish ground engineer Jan Yeomans tells us, “We use jet grouting to build up stabilization in the land mass behind the wall. When the slurry hardens, we’ve got a solid column that keeps the ground mass where it belongs. Fixing the wall that suffered from that mass movement however, is another requirement for repairing the property. Even though the pressure on the wall is reduced, simply spackling it up doesn’t solve the problem. We use Torque Lock to keep it from moving apart and the wall is as good as new.”

Torque Lock Staples ship globally “same-day” and can be ordered directly through the Torque Lock website. See installation videos and how Torque Lock Staples provide the only patented and permanent solution for structural cracking in the industry.

Visit www.torque-lock.com or call 818-436-2953 for questions or orders by phone.