As with any of these temporary repair methods, or any repair made on anything ever repaired in the whole of the universe, it comes down to this: The repair you make is only as strong as its weakest point. AquaStitch Staples Don’t Repair Structural Cracks.

AquaStitch Staples, the same as Kevlar Staples, rebar and all these other contraptions – are epoxied to the pool wall. Do not let the shape of the AquaStitch Staples fool you – it is still glued to the wall.

Below I’ll give you a short list of the many other reasons why they don’t work, but first let’s discuss this epoxy thing.

The AquaStitch is a piece of bent metal that you stick into holes in the pool wall. As per their instructions, you then run a bead of epoxy along the area where you are going to lay the staples and literally glue it to the wall. As we all know, when a crack spreads, the dried epoxy breaks away and the crack gets wider. Gluing a skinny piece of metal rod to the wall doesn’t stop the epoxy from failing. The repair is only as strong as its weakest point.

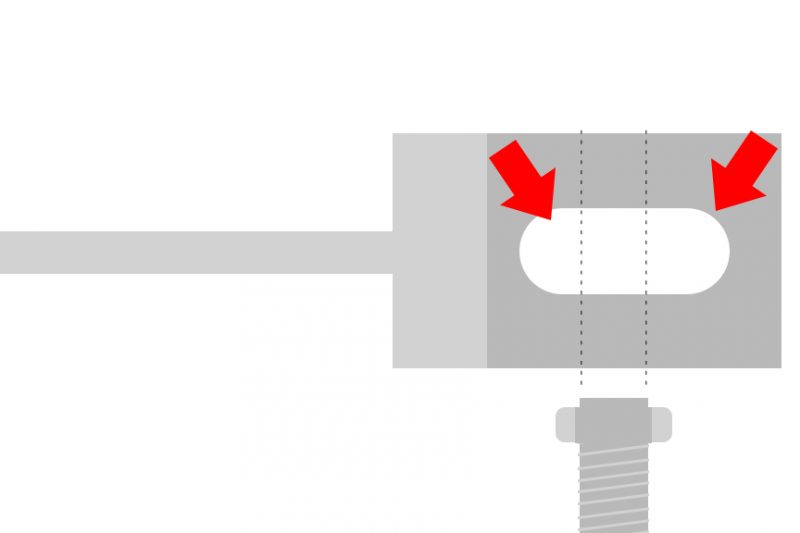

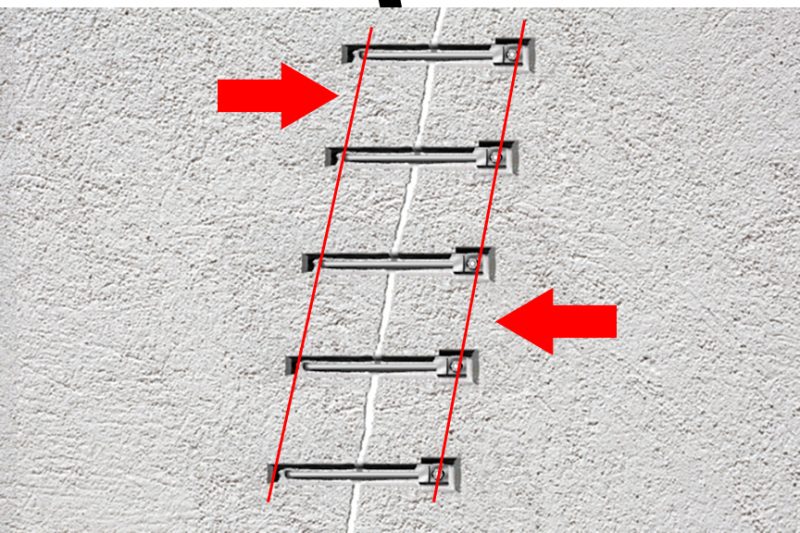

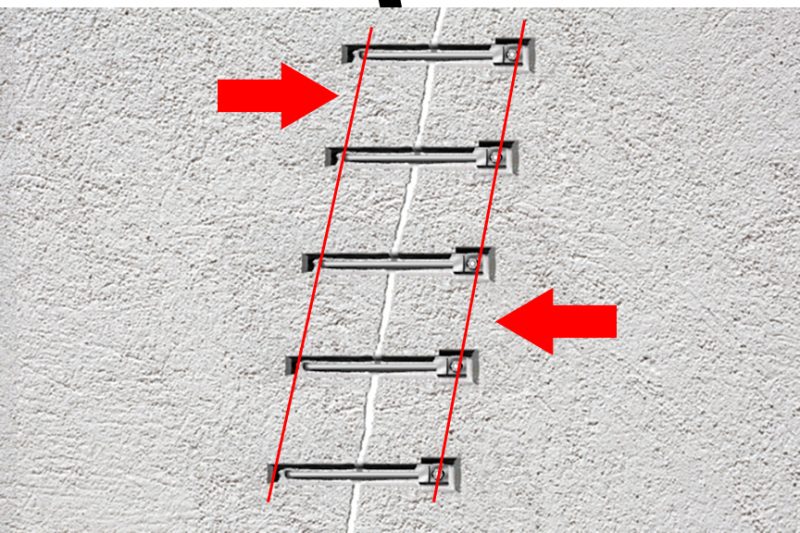

Now, you’ll see in the diagrams, they countersink a bolt into the end of the staple. It has an oval shaped hole to allow the installer to align the staple with the bolt. It kind of looks like the diagram below.

So the big problem here is, as the crack widens, that oval hole is going to move, albeit maybe just an inch – but a crack that widens an inch is going to literally gush water through it and cause the damage to increase exponentially. It doesn’t matter how much epoxy you smear into a crack, when it spreads, that epoxy means literally nothing. It’s another reason why AquaStitch Staples Don’t Repair Structural Cracks.

Then there is this installation method. Aligning holes in a row, alongside an area that is already susceptible to cracking. It invites two more areas for cracks to appear, as they are aligned vertically with one another, reducing the stability of the surrounding concrete.

Now, regardless of what they consider a tensile strength for their metal rod, it’s literally a bent rod. It has a bent elbow, like rebar, and is – no matter what you’re told, still able to bend when literally TONS of concrete decide to make a move. This isn’t good, because while it may be the least of its weakest points, it’s still a weak point that adds to the potential of failure.

This is why the Torque Lock Structural Staple was invented, and like the AquaStitch – many other companies have created a product in an attempt to mimic what the Torque Lock Staple provides – and they have failed to do so.

The Torque Lock Structural Staple AND method of installation are both patented. This means, only the Torque Lock Structural Staples address the needs of a swimming pool owner when making permanent repairs on structural cracks.

The Torque Lock Staple is designed to add upwards of 5000 lbs of controlled compression to either side of a structural crack. Don’t let other brands fool you with talks of tensile strength, it means nothing when a crack wants to shear or spread. Torque Lock Staples guaranteed a COMPRESSION; this is what keeps cracks from moving. AquaStitche’s mention of tensile strength speaks of how much stress a product might take when movement happens, and frankly, anything glued to a wall has literally zero strength to hold it. Compression, however, is direct resistance against the potential for that crack to move at all. Torque Lock Staples are the only product on the market that applies compression. As for the strength of the staple itself – we haven’t found a level of resistance that can break it yet, and that’s no joke! Even at the pressure of what concrete moving can provide, it doesn’t budge, and we can’t make a whole lot more pressure to test it than a few tons of direct pressure from concrete, so we’re confident it’s what you’re looking for.

When installed, the staples have a patented cam that rotates to provide the torqued compression. There is no oval hole and screw that moves that cam. The cam sets permanently and cannot slide, shift or bend when torqued properly. You don’t need to add epoxy to the underside of it to glue it to the wall, the compression causes it’s staying power, and again, you can’t add enough force to remove it. When it’s in, it’s permanent.

We also don’t recommend squirting epoxy into a crack. We’ve offered countless representations in our content about how epoxy fails to penetrate a crack in concrete. You use actual concrete to penetrate and seal the crack, and it’s going to stay where you put it, because the crack has no ability to widen with the controlled compression applied.

Staples are set into the wall at 12 inch intervals, first a six inch staple, then a three inch staple, and then repeat. Because the holes are not aligned, the potential for further concrete cracking is reduced to zero. The application of installation, like the staples themselves, is also patented, which is why these other companies don’t offer it as an option.

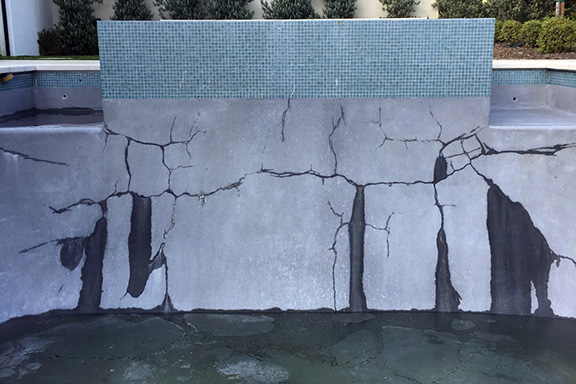

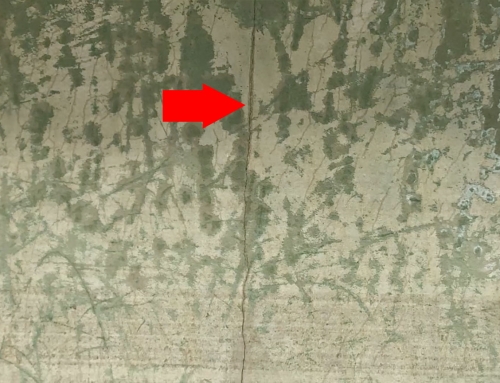

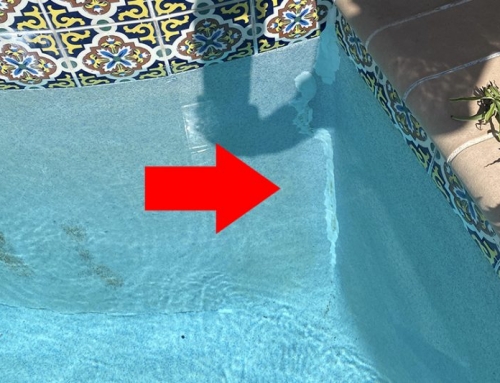

Torque Lock Staples are used the world over to save foundations, solid concrete structures like fountains and sea walls and of course – swimming pools. The hardest hit areas where concrete fails are easily repaired using Torque Lock Structural Staples, and size doesn’t matter. Look at this Lazy River in Orange Beach, Alabama. They repaired more than 2000 linear feet of cracks and that pool is now water tight. How many feet of crack do you have? I bet we can fix it.

Now is the time to make the permanent repair your pool needs to last a lifetime. Don’t take the cheap way out and trust in epoxy injection, glued on fiber strips or bent metal. You’ll be paying to rip it out and having t install Torque Lock Staples later – avoid the hassle and do it right the first time.

Click here to order your staple kits and call 818-436-2953 at any time to ask questions, get assistance by phone or to place contractor orders.