With summer in full effect, and many areas that are normally teaming with foot traffic closed due to Covid restrictions, homeowners and municipalities are taking advantage of this time to make necessary repairs to concrete structural cracks and are extending the lifespan of solid concrete structures with Torque Lock Structural Staples.

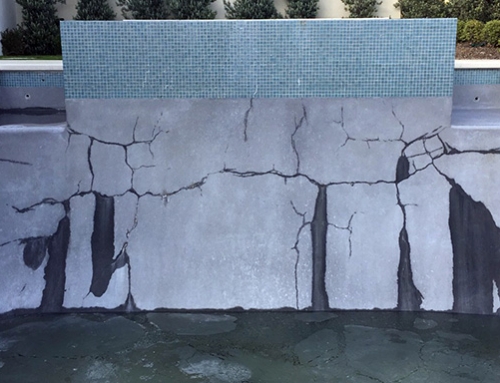

Swimming pools, concrete slabs, foundations, sea walls and a variety of solid concrete structures that suffer from cracks forming are getting extended lifespans with permanent repairs using Torque Lock Structural Staples. With its controlled compression, ensuring that it won’t re-crack or spread is extending the life of these structures by decades and is giving a freedom from concern for Torque Lock users.

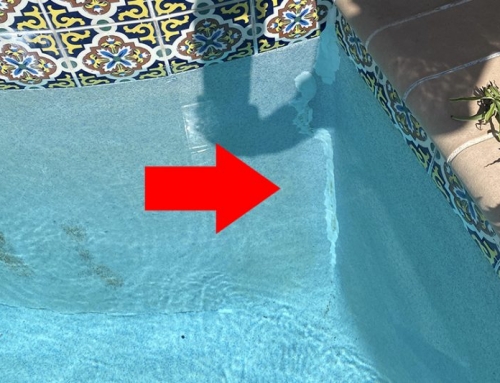

Before winter rolls in and water expansion due to freezing adds more stress and strain to already formed cracks, contractors are stopping damage with a simple repair installation that keeps concrete in place. The repairs end the threat of continued cracking and stabilize structures for years of future use, here’s how.

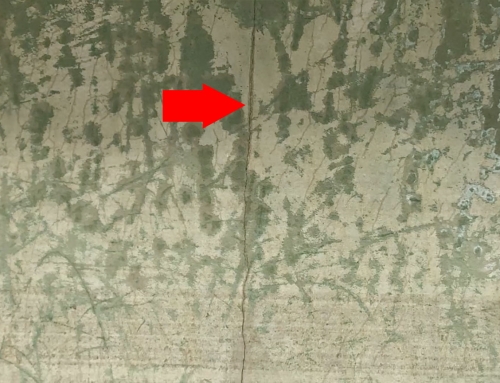

When cracks form, the easily have the potential to lengthen and widen. The force and pressure that causes cracks to extend is typically behind the structure and it isn’t going away. To keep concrete from moving, a firm pressure needs to be applied to combat the movement. Torque Lock Structural Staples apply the only protection to keep concrete still. Each staple uses a torqued compression from the patented offset cam of the staple. Installed at every liner foot, the staples provide up to 5000 lbs of compression to combat movement, literally stitching the affected area with an insurmountable strength that assures movement, shearing, spreading and re-cracking is not an option.

The structure is repaired using a spec-mix or hydraulic cement that penetrates the cracked area and forms a permanent bond. Water seepage, separation and movement from the backfill behind the structure simply cannot cause further damage to the crack. It’s a guarantee that products like epoxy injection and carbon fiber cannot provide. Only Torque Lock’s Cold Rolled Steel Design can provide the compression needed to resist cracks from spreading. No fiber product or epoxy injection can do that.

When installed at 12 inch intervals down the length of the crack, 1 staple per foot, an equal compression is spread throughout the concrete on either side of the crack. No need to pack multiple staples in one area, as the entire shell or wall is a solid mass, it moves together when it does move. With the staples marked, drilled and set in at each one foot interval, the concrete is secured along the entire length of the crack.

When cracks are permanently repaired using Torque Lock, extending the life of solid concrete structures can give them a whole new lifetime of support. Sea walls double their lifespan in torrential coastal areas, swimming pools that homeowners considered for demolition have years of enjoyment given back to them with Torque Lock repairs and even basement floors that have been subject to fluctuating water tables and cracking have seen repair and a dry finish by using Torque Lock to make permanent repairs.

Torque Lock Staples are the trusted solution for permanent crack repair around the world. Shipped directly from the manufacturer, Torque Lock Staple Kits are available in 10 foot, 30 foot and 50 foot packs to cover any size or amount of cracking a job requires. Torque Lock Staples are shipped direct to the consumers door and install with simple hand tools. Visit https://torque-lock.com to see video content explains installation, read users guides or to place orders.

For more information or to order Torque Lock Staples by phone, call 818-436-2953 today.