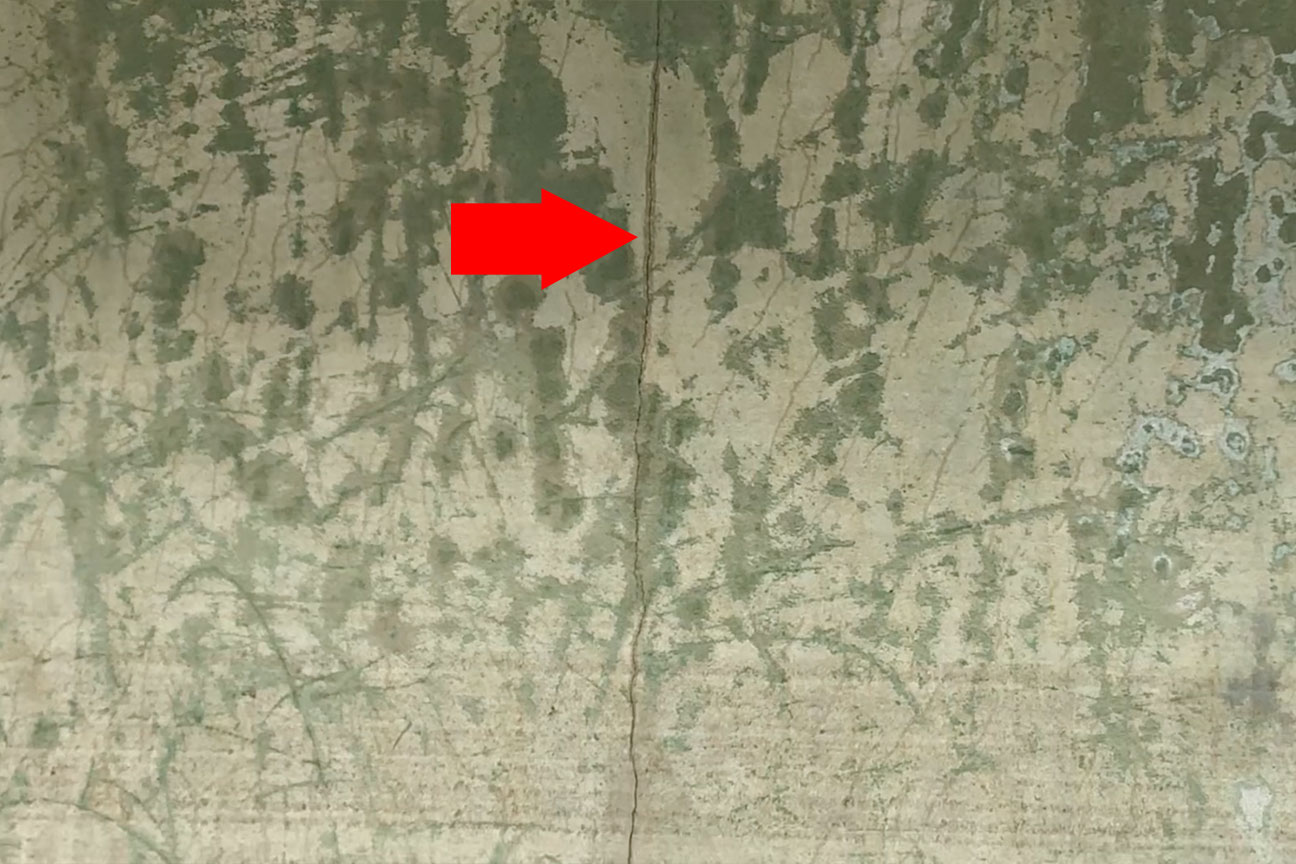

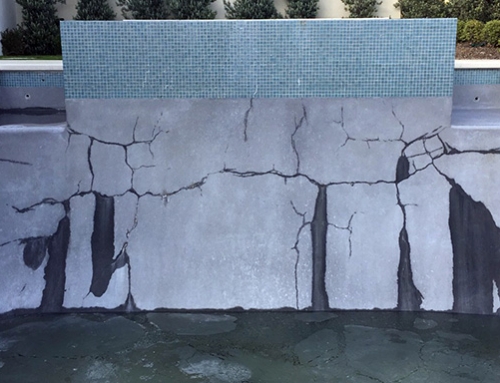

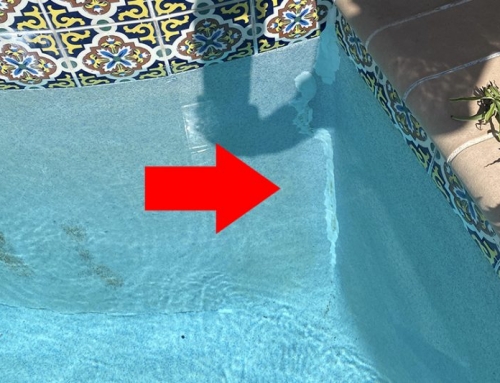

When performing a proper leak detection, one of the things we take note of is structural cracking in the pool. Seeing what appears to be a crack in a pool may just be a surface crack, one that runs along the 1/2 inch of plaster over the surface of the pool. While it isn’t an immediate danger to the health of the pool, the fact that water will penetrate the area, it is likely that bigger problems will prove themselves with time. Repairing structural cracks and leaks is important to extend the life of your swimming pool.

It is natural that concrete pools will lose water. Concrete is, by nature, a porous material and subject to leaching water from the pool. Concrete pools, even with a dense mortar finish, are subject to this and with time and age, they wear and become less resistant to water loss. While some homeowners may opt to apply temporary rubber based paints and refinishes to the surface of their concrete pool, addressing structural cracks with proper repair is the most important thing you can do to improve the longevity of your investment. If you discover a structural crack in the shell, fix it right the first time.

A proper leak detection is performed using highly sensitive hydrophones that listen for water escaping through cracks and separations in the concrete. Cracks can appear in the floor, walls, corners or even around fittings, drains and lights. Using the PoolScope from LeakTronics, a powerful omnidirectional hydrophone found in the Pro Complete Leak Detection Kit, technicians can hear water escaping through a crack. By dropping the PoolScope onto the crack and listening along it, wherever water is escaping, the sound can be heard, accurately, and the precise location of damage is identified.

Repairing the crack properly with Torque Lock Structural Staples will ensure that the potential the crack has to spread, or reopen is removed. With Torque Lock’s controlled compression applied to either side of the crack, it simply can’t spread. When the crack is repaired using a fully penetrating concrete or spec mix, it hardens into a permanent repair and the pool is finished over to a perfect and leak free shell.

Torque Lock installers will drain the pool and use a method called Misting and Mapping to identify the full length of the crack. By spraying a light mist of water over the area in question, dry cracks will retain the moisture for a period of time, about 20 minutes. This allows the repair contractor to outline the crack from start to end. Using a wax crayon, the complete area of repair will be visible and the work can begin.

The contractor will mark around the crack with the Torque Lock Staple Templates, marking where the installation will happen. This includes marking where the holes will be drilled into the concrete to allow for insertion and controlled compression.

Once marked, and holes drilled, the contractor will cut a wide channel around the crack, through the mortar surface of the pool. The depth of the channel is minimal, but it allows the contractor to set the staples below the surface level of the pool so refinishing is smooth. The staples are seated with a permanent post in one hole and the adjustable cam post in the other. The cam is off-set and allows for turning, or torquing the post into a position where it applies up to 5000 lbs of compression to either side of the crack. What this does is, it resists a cracks ability to separate or shear. The compression keeps the movement of the shell at bay and when placed every 12 inches of linear footage down the crack, it is permanently set with the strength to resist pressure or force; it’s the only method that works for repairing structural cracks.

The wide channel is covered over, and the crack is filled, with a hydraulic cement. It dries to a permanent fixture, literally becoming part of the shell. The contractor will cover the area with a waterproofing membrane for added protection and the channel will be smoothed over to match the surface of the surrounding area. Once filled, the pool and the structural crack, will be sealed and leak free.

The cost of fixing a pool properly with Torque Lock Staples is more than what someone might pay to have an underwater epoxy smeared into the cracks but epoxies don’t fix cracks. They make a temporary plug for water escaping; but it is temporary. Water will eventually penetrate the epoxy and the damage from the crack will spread, widening and causing water loss again. It only makes sense to fix it right the first time and never have a concern for the crack again.

Torque Lock Staples are installed using basic hand tools and it is a job that any contractor can perform. The Torque Lock Website, https://torque-lock.com, features how-to videos and customer support is available by calling 818-436-2953 with any questions about installation, or to place orders.

Unlike fiber and kevlar straps and rebar which bend, break and even rust out, Torque Lock Staples are permanent, and are the only patented repair method that offers the permanent repair of structural cracks. Do not accept a cheap substitute, you’ll end up disappointed when it fails a year later, or less.

Learn more now at https://torque-lock.com and order your staple kits to begin repairing structural cracks and leaks on concrete pools today.